Q-Tile XT outperforms sintered tungsten carbide products (Cermets) in several critical wear applications while maintaining extremely high impact durability thereby

exhibiting the best properties of both the ceramic and metallic worlds.

The Q-Tile family (Q-Tile Gen-1 and Q-Tile XT: wear coatings and wear tiles) offers cost-effective solutions to protect critical equipment that is exposed to extreme multi-modal wear mechanisms. It is especially well-suited to protect against slurry erosion – abrasive-erosive wear degradation in potentially corrosive environments.

Q-Tiles deliver unmatched protection in its applications in Oil Sands, Oil & Gas, and Mining, where downtime and maintenance are costly. By using our tiles, our partners can cut planned and unplanned outages and benefit from the increased throughput provided by longer service lives in their most critical equipment.

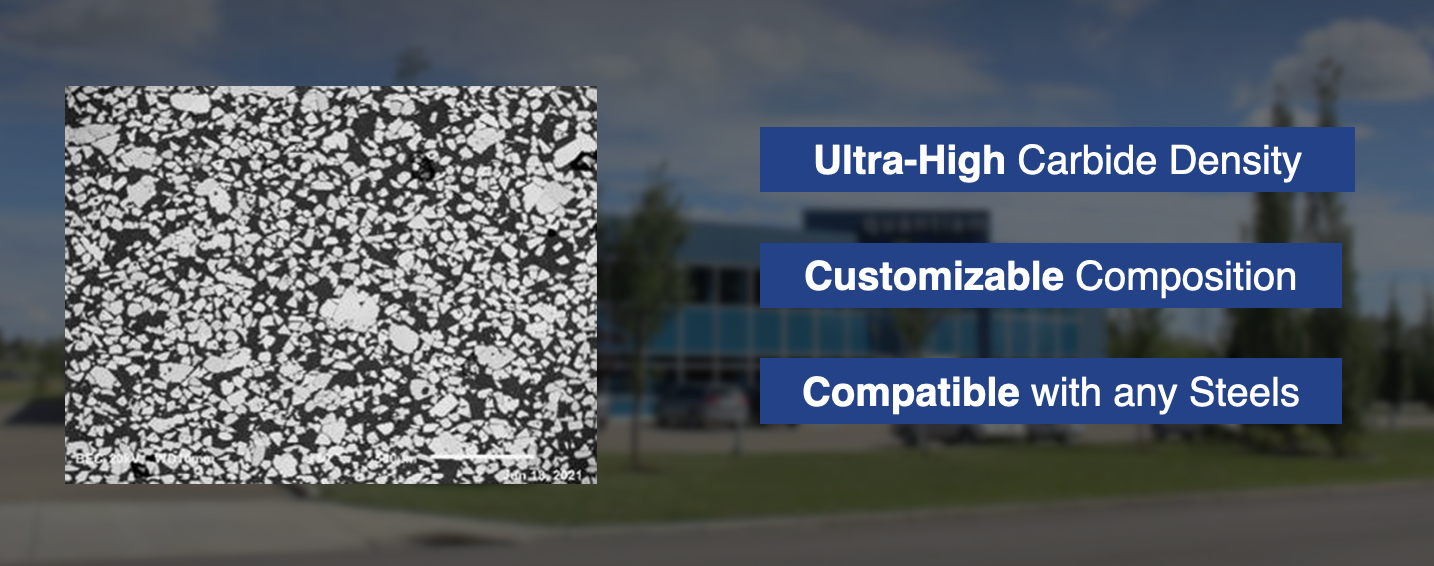

Q-Tile's are distinct from traditional tungsten carbides in that they consist of tungsten carbide particles embedded within an alloy matrix, providing a variety of structural and performance qualities:

Q-tiles are classed as metal matrix composite materials, with a fully-consolidated, dense microstructure.

Customizable carbide densities can range from 50% up to as high as 80+%.

Composite alloy matrix has inherent corrosion resistance, outperforming Co- and Fe-based alloys.

Q-Tiles exhibit near-zero porosity (<0.5%).

Shear bond strength exceeds 50ksi (344 MPa).

Tiles can be MIG welded on-site or vacuum fused to a wide range of steels.

Proprietary microstructure can be customized to include varying sizes, morphology, and loading of selected carbides within the composite matrix are customizable and can be tailored to best suit specified performance requirements.

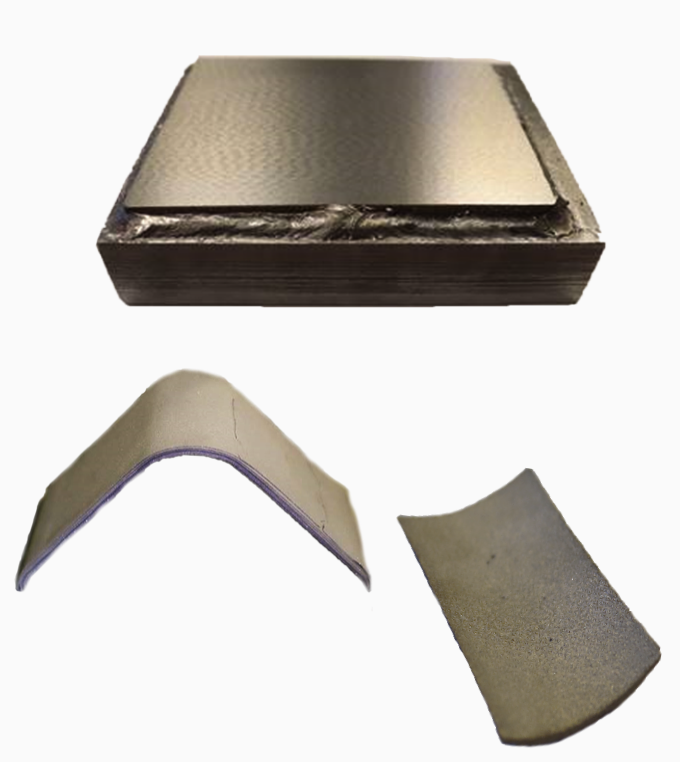

Optimal performance in applications exposed to steam-based slurries. Can be used to coat non-line-of-sight, internal tubular surfaces. Available as a wear tile with high latitude in X-, Y-, and Z-dimensions, 2mm to 25mm (Z), up to 500mm x 500mm per tile (X-Y). Can be used to cover/protect complex shapes.

Unparalleled wear performance with high impact strength, best suited for applications with extreme levels of abrasive and erosive wear (slurry erosion), and where high-energy impacts are expected. Available as a wear tile with high latitude in X-, Y-, and Z-dimensions, 2mm to 25mm (Z), up to 500mm x 500mm per tile (X-Y). Can be used to cover/protect complex shapes.

| Test Standard | Units | Q-Tiles

(formulation-dependent) |

AR400 | D2 Tool Steel | HCWCI 28Cr |

|---|---|---|---|---|---|

| ASTM G65 | Volume Loss (mm³) | 3.2 to 5.0 | 52.6 | 35.6 ± 5.2 | 16.8 - 22.6 |

| Mass Loss (g) | 0.05 to 0.07 | 0.42 | 0.24 - 0.32 | 0.14 - 0.26 | |

| ASTM G99 | Pin on Disk (µm³) | 1.1 to 2.0 | — | 6.9 × 10⁶ | 2.39 × 10⁷ |

| NRC SJE | Volume Loss (mm³) 90° | 0.6 to 0.9 | 75.0 | 24.4 | 14.4 |

| Volume Loss (mm³) 45° | 0.7 to 1.0 | 126.0 | 25.9 | 12.8 | |

| Hardness | HRC | 50 to 60 | 40 | 60 | 56 |

| Vickers - Matrix | 575 to 850 | 370 | 818 | 812 | |

| Vickers - Hard Phase | 1500 to 2000 | — | — | — | |

| ASTM G171 | Scratch Hardness (GPa) | 9.4 to 10.7 | 3.4 | 2 | 9.1 |

| ASTM B 406-96 | Transverse Rupture (MPa) | 1197 to 1244 | N/A | N/A | 984 |

| Innotec Rotary Impact | Mass Loss (g) | 0.003 to 0.008 | N/A | N/A | N/A |

| Carbide Area Fraction | % by Image analysis | 52.7 to 65 | N/A | N/A | N/A |

| Carbide Sizes | µm | 1.5 - 177 | N/A | N/A | N/A |

| Porosity | % | < 0.5 | N/A | N/A | N/A |

| Density | g/cm³ | 10.5 to 11.0 | 8.0 | 7.7 | 6.8 |

* AR400 Abrasion-resistant Steel

* D2 Tool-grade steel

* High-Chromium White Cast Iron

Download our Q-Tiles (Wear Tiles) Brochure for more information

Download our Q-Tiles (Wear Tiles) Brochure for more information