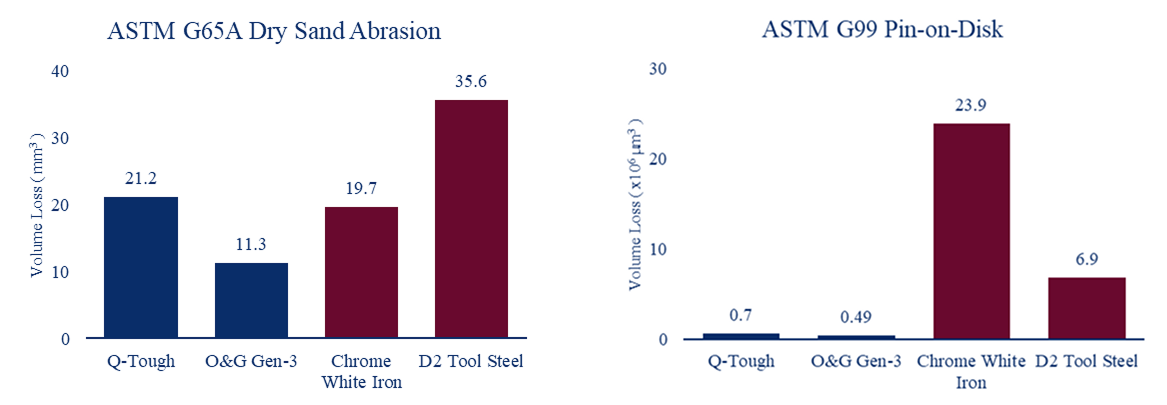

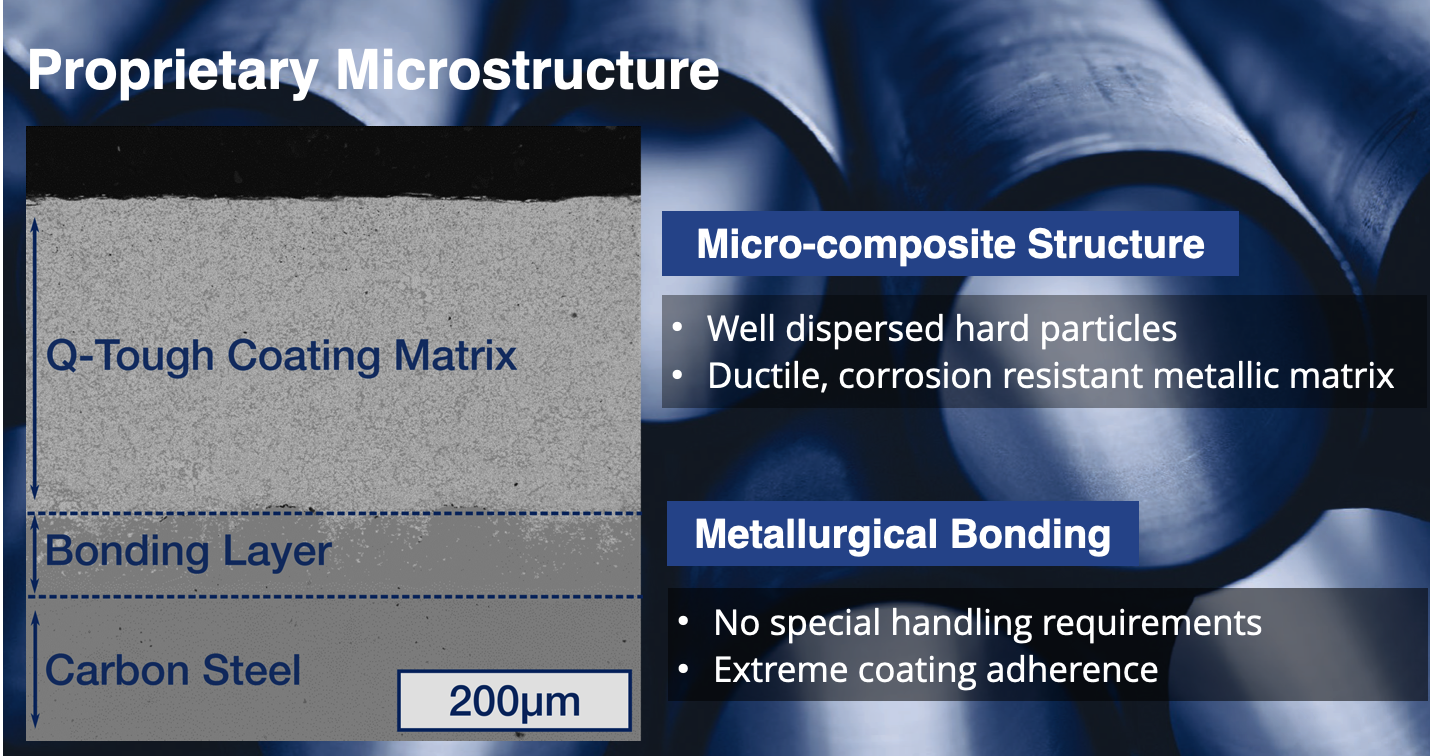

Q-Tough (Gen-1, Gen-2 and Gen-3) are specialized coatings consisting of sub-micron, well-dispersed transition metal carbides, silicides, and borides generated in-situ in a ductile corrosion-resistant metallic matrix. The coatings are designed to perform reliably in applications facing extreme levels of sliding wear. Standardized ASTM G99 pin-on-disk sliding wear testing shows Q-Tough delivers 10X the performance of D2 tool-grade steel, and over 20X the performance of high-chromium white cast iron.

In addition to delivering best-in-class sliding wear protection, the as-produced surface finish is very smooth and Q-Tough delivers significantly longer run-times for coated equipment while reducing wear and tear on mating components, metallic, coated or organic. Field trials in oil wells (shale gas and tight oil service) show service life extended by over 4X (for Gen-1 alone), drastically reducing the frequency of costly, resource-intensive workovers and increasing reliability, resulting in annual savings of over US$75,000 per well.

The coating can be applied to both external and/or internal (non-line-of-sight) surfaces, currently to a thickness of up to 1.5mm. Field-proven performance in O&G production tubing, with applications in many additional down-hole components. In accelerated wear testing for PCP rotors, the coating has exhibited excellent wear resistance, low friction and has been identified as “Teflon-like” in terms of its low friction coefficient, reduced energy requirements and extending the life of mating elastomer stators.

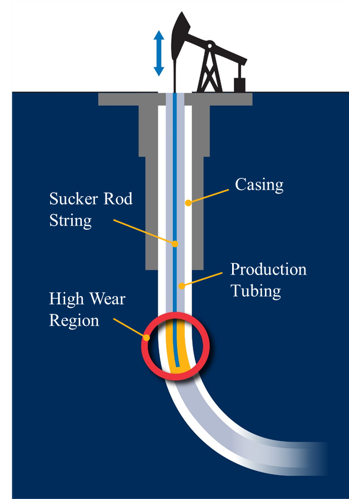

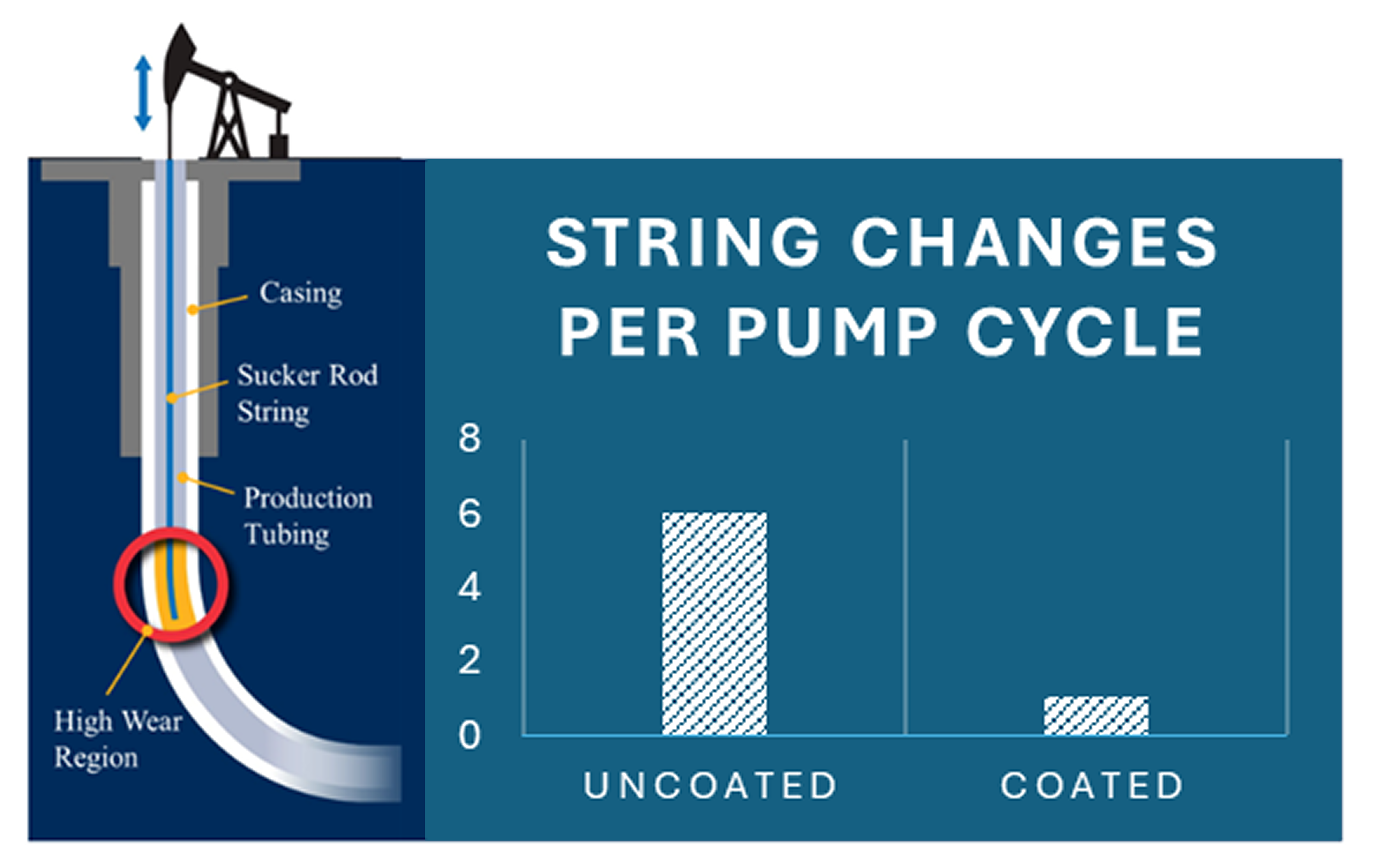

Q-Tough coated tubulars address the sliding wear problems in sucker rod-driven wells which cause production tubing perforations and lead to a high frequency of tubewall failures and costly downtime and workovers.

Production tubing lasts longer when Q-Tough is applied at high-wear locations, eliminating resource intensive workovers, reducing costs, and increasing reliability.

* High-Chromium White Cast Iron

* D2 Tool-grade Steel

Comparable performance to Chromium Carbide overlays and white cast iron in slurry jet erosion tests, 93% of coating thickness remains after 500+ days in field service.

Field trials of Q-Tough coatings have been installed in 44 wells in the Bakken region of North Dakota.

| Test Standard | Units | Q-Tough | O&G G3 | AR400 | A335 | D2 | HCWCI 28Cr |

|---|---|---|---|---|---|---|---|

| ASTM G65 | Volume Loss (mm³) | 21.2 | 11.3 | 52.6 | 64.5 | 35.6 ± 5.2 | 16.8 - 22.6 |

| Mass Loss (g) | 0.17 | 0.10 | 0.42 | — | 0.24 - 0.32 | 0.14 - 0.26 | |

| Coriolis | Vol loss (mm³/kg) | 0.236 | 0.061 | — | 4.550 | — | 0.097 |

| ASTM G99 | Pin on Disk (μm³) | 7.0 × 10⁵ | 4.9 × 10⁵ | — | 4.5 × 10⁶ | 6.9 × 10⁶ | 2.39 × 10⁷ |

| NRC Slurry Jet Wet Erosion | Volume Loss (mm³) 90° | 18.0 | 13.1 | 75.0 | — | 24.4 | 14.4 |

| Volume Loss (mm³) 45° | 17 | 11.6 | 126.0 | — | 25.9 | 12.8 | |

| Volume Loss (mm³) 20° | 5 | 3.2 | 85 | — | — | — | |

| Hardness | HRC | 61 | 64 | 40 | 25 | 60 | 56 |

| Vickers - Matrix | 1035 | — | 370 | — | 818 | 812 | |

| Vickers - Hard Phase | — | — | — | — | — | — | |

| ASTM G171 Scratch Hardness | Scratch Hardness (GPa) | 14.20 | 19.20 | 3.39 | 2.70 | 2.03 | 9.14 |

| Innotec Rotary Impact | Mass Loss (g) | — | 0.003-0.008 | — | — | — | — |

* AR400 Abrasion-resistant Steel

* A335 Chromium-molybdenum Alloy Steel

* D2 Tool-grade Steel

* High-Chromium White Cast Iron

Download our Q-Tough Brochure for more information

Download our Q-Tough Brochure for more information