Quantiam has developed a world-class protective coating that is the optimal solution for equipment exposed to repetitive, high-energy impacts. The coating delivers additional sliding and abrasive wear-resistant properties, protecting critical equipment from both impacts and subsequent wear mechanisms.

Work-Hardening material ("WHm") coatings and coated tiles deliver a protective material metallurgically bonded to external surfaces of equipment and Ground Engaging Tools (GETs) under extreme service conditions, like Oil Sands excavator bucket teeth, shaker screen and ore discharge chutes. WHm exhibits excellent wear resistance, toughness and hardness in operation.

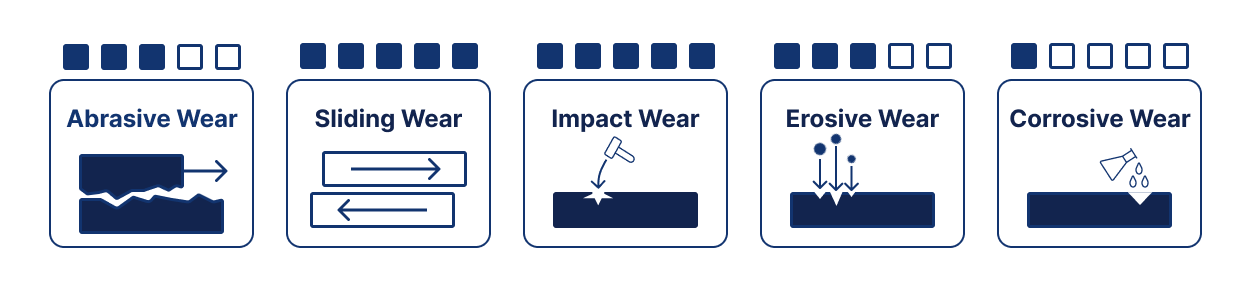

GETs used in the mining extraction sector, including Alberta’s Oil Sands, degrade by a combination of abrasive, erosive, and impact wear mechanisms. Quantiam’s Q-Coats Family encompasses new coating products for Mining and Oil Sands-related customers which combat this unique combination of wear mechanisms and show best-in-class wear resistance, namely a work-hardening matrix (WHm) and hard particles (WC-based carbides) in a coating or tile material resulting in an extreme wear-resistant product, WHm.

The WHm coating undergoes work-hardening through operational use, resulting in increased hardness and wear performance following each consecutive impact. Additionally, its notable sliding and abrasive wear performance offer added protection against additional wear mechanisms attacking the part's contact surface after the initial impacts.

The increase in wear resistance is primarily due to strain-hardening developed via the generation of dislocations within the material that form as the component is worked. The WHm chemistry impedes further movement of dislocations significantly increasing wear resistance and hardness without causing embrittlement.

As the surface and coating matrix or as a monolithic tile work-hardens and toughens from impact, abrasion or sliding wear, these structural changes translate in to significant extension of the service life of coated equipment.

WHm has modest corrosion resistance and is best-suited to environments where equipment faces minimal amounts of degradation due to chemical attack.

WHm is available as a coated-steel wear plate or as standalone coating on complex geometries. Additionally, crushed carbides, carbide inserts or other coarse carbides can be embedded within the coating matrix for even greater wear resistance or improved friction properties.

WHm is well-suited to protect ground engaging tools (GETs), especially when improved wear profiles are important alongside improved wear rates. Immediate market applications include shovel bucket teeth and grader blades.

| Test Standard | Units | WHm | AR400 | A335 | D2 Tool Steel | HCWCI 28Cr |

|---|---|---|---|---|---|---|

| ASTM G65 | Volume Loss (mm³) | 5.9 - 12.5 | 52.6 | 64.5 | 35.6 ± 5.2 | 16.8 - 22.6 |

| Mass Loss (g) | 0.09 | 0.42 | — | 0.24 - 0.32 | 0.14 - 0.26 | |

| ASTM G99 | Pin on Disk (µm³) | 9.0 × 10⁵ | — | 4.5 × 10⁶ | 6.9 × 10⁶ | 2.39 × 10⁷ |

| NRC SJE | Volume Loss (mm³) 90° | 3.0 | 75.0 | — | 24.4 | 14.4 |

| Volume Loss (mm³) 45° | 3.9 | 126.0 | — | 25.9 | 12.8 | |

| Hardness | HRC | 64 | 40 | 25 | 60 | 56 |

| Vickers - Matrix | 850 | 370 | — | 818 | 812 | |

| Vickers - Hard Phase | — | — | — | — | — | |

| ASTM G171 | Scratch Hardness (GPa) | 10.92 | 3.39 | 2.70 | 2.03 | 9.14 |

| Innotec Rotary Impact | Mass Loss (g) | 0.003 | — | — | — | — |

* AR400 Abrasion-resistant Steel

* A335 Chromium-molybdenum Alloy Steel

* D2 Tool-grade Steel

* High-Chromium White Cast Iron