Quantiam has developed disruptive, best-in-class coatings and monolithic materials (tiles) for the most demanding wear environments found in the Oil Sands, Oil & Gas and Mining sectors. Our products have achieved unique properties of both metallic and ceramic materials and deliver unparalleled performance offering solutions to protect critical operating equipment reliably and cost-effectively.

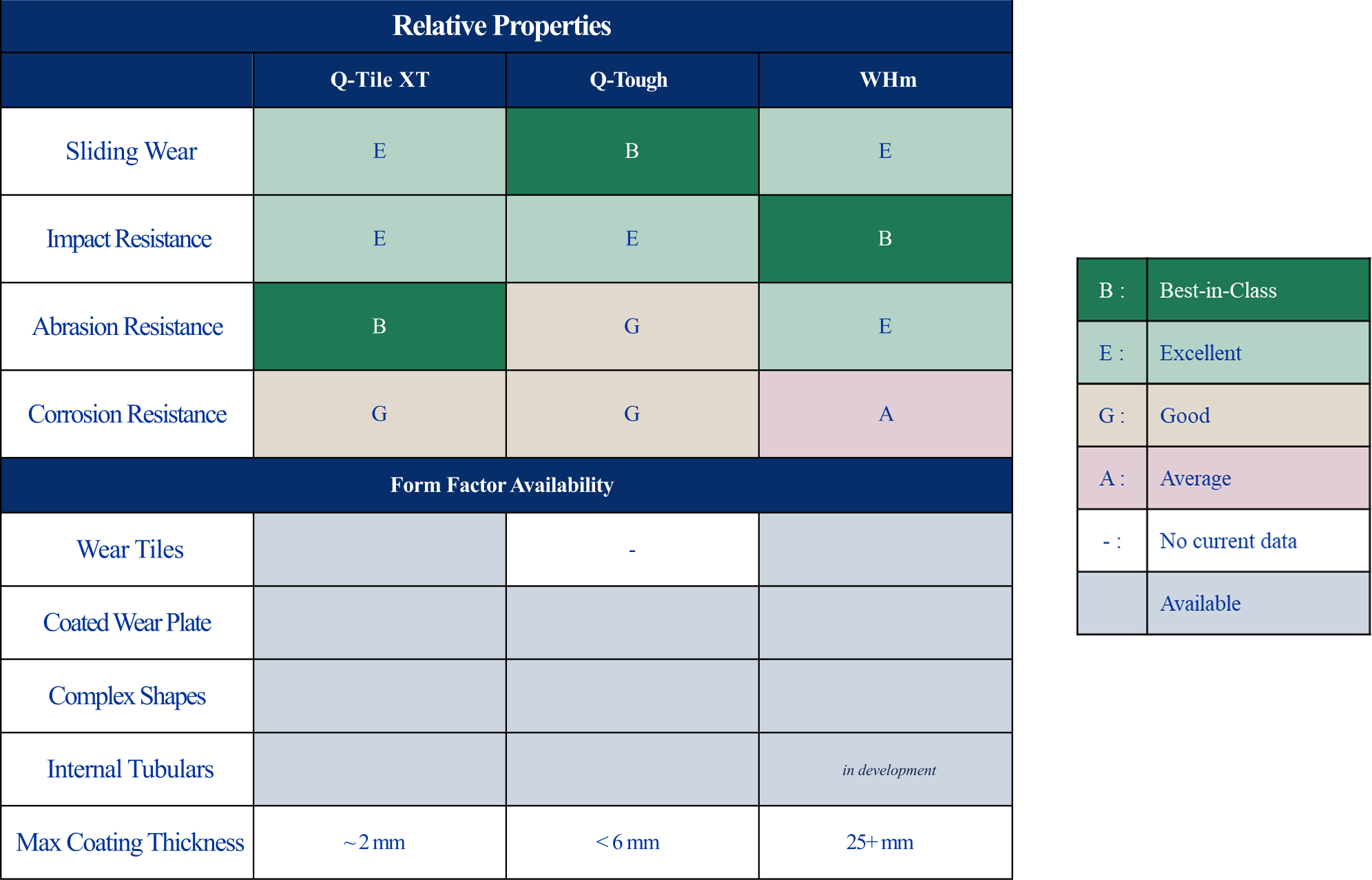

Three new platform technology families have been advanced to Technology Readiness Level 8 (TRL-8), namely, Q-XT/Gen-1 Tiles, and Q-Tough and WHm Coatings, each with unique properties and benefits as described below. The company is capitalizing to launch its first commercial-scale Wear Products facility to serve primarily the Alberta and North American markets.

Q-Tiles are an economical solution to applications that require the highest possible abrasive and erosive wear resistance. They deliver comparable wear performance to the best sintered tungsten carbide materials (Cermets) at a fraction of the cost, and are significantly more durable and impact resistant.

Our monolithic metal matrix composite (MMC) tiles are ideal for wear and abrasion protection applications, offering an excellent blend of metallic and ceramic properties.

Tiles can be directly MIG welded to surfaces and can be vacuum fused onto steel backing.

Our portfolio includes specialized formulations designed to address a wide spectrum of application scenarios.

With “Teflon-like” friction reduction and extreme hardness and wear protection, Q-Tough is the optimal wear-resistant coating system for combatting dry-sliding and abrasion wear in high-performance industrial applications.

It is ideal for applications requiring low friction and high hardness, and shows minimal wear on metallic or coated-mating surfaces.

System can be applied via non-line-of-sight deposition, and is applicable to internal and external tubular shapes.

Compatible with carbon steels and alloys.

WHm ("Work-Hardening material") is a self-work hardening wear reisistant coating system ideal for Ground Engaging Tools (GETs).

It delivers exceptional impact resistance along with impressive protection against abrasive (dry & wet) and sliding (dry) wear.

WHm coatings can be applied via non-line-of-sight deposition to internal and external tubular and complex shapes. It is also available in the form of coated wear plates and wear bars.

Compatible with Mild Steel, Stainless Steels and Nickel Alloys.